0113 3909670 | 0800 7797472 | 0770 3020260

Hi, welcome to MPS Electrical Ltd Thermographic Imaging Electrical Surveys page, we are 18th edition City & Guild Electrical Approved, Domestic, Commercial & Industrial Electrical Contractors in Leeds.

We specialise in Electrical Inspection & Testing & conduct Thermographic Imaging Electrical Surveys Surveys on any property for peace of mind, routing maintenance or to satisfy insurance companies to ensure no electrical issues are apparent.

We conduct electrical thermographic surveys in Leeds, Bradford, Wakefield, York & Harrogate. We stretch further a field for our commercial customers and work nationwide if required to.

Thermal Imaging

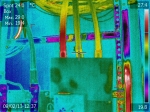

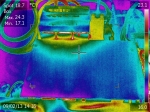

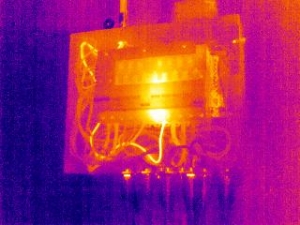

Using thermal imaging, our electricians can accurately identify existing faults with an electrical installation, as well as predict potential future issues that could save lives and stop the property catching fire.

Thermal Imaging Leeds

By detecting electrical anomalies often invisible to the naked eye on electrical installations such as burning lose electrical connections inside mains consumer units both single phase and three phase, thermography allows corrective action to be taken before catastrophic costly system failures occur.

Electrical Thermal Imaging Reports or Thermography reports is the process of using a special camera designed to look only for heat by way of infra red (IR) energy waves. Potential problems can often be found due to excess heat being released by an electrical system, even those which would normally produce some heat when performing at their optimum level.

If Electrical heat build up issues within electrical installations remain undetected these problems can lead to failure and an electrical fire, almost certainly an expensive production loss or downtime and, in the most extreme case it can lead to an electrical fire.

A regular inspection of thermal imaging as part of reactive routine maintenance can highlight potential problems long before any event.As a result any required electrical replacements or repairs can be planned for in terms of both time and budgets.

In short, it is an invaluable resource for predictive maintenance. Thermography has applications in many different areas which are listed below.

Thermography can detect the following in electrical systems in Leeds before they cause a problem:

- Loose connections

- Overloads

- Phase imbalances

- Corrosion

- High resistance in fuses and switch gear

Thermography can detect the following in mechanical systems in Leeds:

- Motor overload

- Worn Bearings

- Boiler seal leakage

- Insulation breakdown

- Hydraulic, steam and hot water systems

- Tank levels and insulation

- Valves

- Turbines

Thermography can detect the following in buildings in Leeds:

- Continuity of insulation

- Flat roof leakage

- Heating, ventilation and air conditioning

- Cold storage thermal gain

- Seals

Electrical Inspection And Thermographic Testing Testing in Leeds

Why do I need to carry out Electrical Inspections – Thermal Imaging?

The Electricity at Work Regulations of 1989 requests a “duty of care” on landlords and employers to maintain electrical systems to prevent danger. Thermal imaging is a widely used method as it can identify problems that the naked eye cant and it is non-invasive or intrusive. Thermal imaging can detect potential problems within the electrical distribution system without the need to isolate circuits. Images can be taken of key components captured in a thermal image and a digital image. Thermal imaging gives you the ability to carry out live testing whilst meting your obligations under legislation.

Who should do the work?

This type of work must be carried out by a qualified and experienced 18th edition Electricians qualified to City & Guilds.

All of our Electricians are fully qualified electricians who have experience of test and inspection.

What is thermographic testing all about?

Thermographic inspection of electrical infrastructure using infrared cameras in Leeds that indicate temperatures. This is known as thermography or radiometric thermal imaging and applied to open switch gear, electrical panels, distribution boards, switches, tap offs, bus bars, and other electrical items. Our inspections utilize Load Correction electrical formula that helps to assess electrical components. These formula offer:

- Load Corrected temperature which estimates temperature based on maximum load

- Fault severity taken from differential between Load Corr and British Standard cable Reference temp set at 75C (65-85C)

- Maximum amps that can be safely run without exceeding the BS Reference temperature set at 75C (65-85C)

Incentive to inspect Leeds Properties?

By producing a detailed report by a trained professional will help demonstrate that reasonable steps have been taken to ensure you’re electrical infrastructure is of reasonable integrity. Additionally, it may satisfy your insurance company requirements for the fire prevention in electrical systems related scenarios.